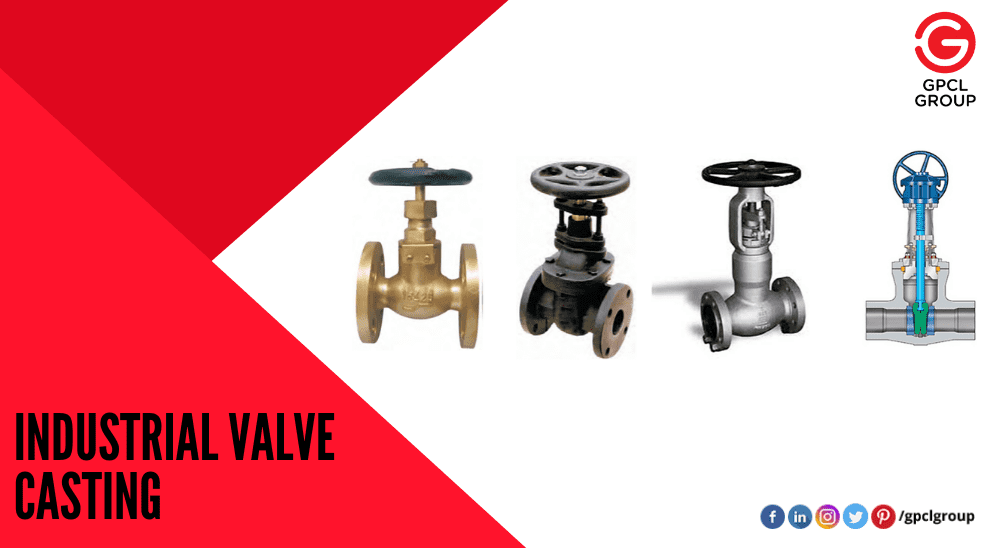

Industrial valves are work as doors to control the in or outflow of gases, slurries, liquids, or some other industrial fluids. The flow of these elements can be controlled with the help of industrial valve castings.

Depending on the purpose they are designed to serve, valve casting manufacturers have made valves of various kinds. These valves have different features and perform different kinds of functions accordingly. In this article, you will come across some popular types of industrial valves and their advantages.

Gate Valves And The Advantages Offered By Them

Gate valves work as isolation valves. These valves restrict the natural flow of fluids through industrial pipes. They are usually affixed to pipelines and can help in starting or stopping the flow of water or any other kind of fluid. These valves are generally made of different materials, such as cast iron, stainless steel, alloy steel, and many more. When the valve is made to obstruct the path of a fluid, the gates shut and vice versa.

Advantages Of Gate Valves

1. The friction loss is very less.

2. Pressure loss can be negligible.

3. They help to save a lot of energy.

4.They are cost-effective.

Throttle The Flow With Globe Valves

This kind of valve designed by the valve casting manufacturers uses the position of a disk, which is movable, which is coupled by a ring seat which remains stationary, to obstruct the flow of fluid. These valves have a baffle that splits the interior of the pipe into two halves. Through its spherical shape, a globe valve is named thus.

Advantages of Valves

1. They eliminate even the slightest chance of leakage.

2. The time needed for opening and shutting the valves is short.

Limit The Fluid Flow With Butterfly Valves

Butterfly valves are another popular kind of valves designed by the valve casting manufacturers. These valves have a limited capability of control. The valves operate efficiently; the handle is rotated 90 degrees to open or close the valve. A metallic disc is placed inside the valve's body. The disc is positioned in a way that remains perpendicular to the flow when it is in the closed position. Intermediate rotations of the valve and the disc allow the regulation of the fluid flow, and controlled by mechanically or manually.

Stated Below Are The Advantages Offered By Butterfly Valves:

1. They are accurate.

2. They do not need a pipe system dislocation.

3. They are reliable.

4. They do not need much maintenance.

Apart from these, two other kinds of valves find their way into being the most common valves for industrial purposes. Ball valves are the valves that harness the ball's use to regulate the flow of fluids from opening to another. Another kind of valve which deserves notable mention is a check valve. A check valve is one which not only obstructs the flow of fluids but also makes sure that fluids do not reverse back into a system. This gives you a fair idea about the different kinds of valves and their advantages.